TEXTILE MACHINERY NATIONAL

COIMBATORE, TAMIL NADU, INDIA

By IFAB MEDIA - NEWS BUREAU - July 18, 2024 | 826 3 minutes read

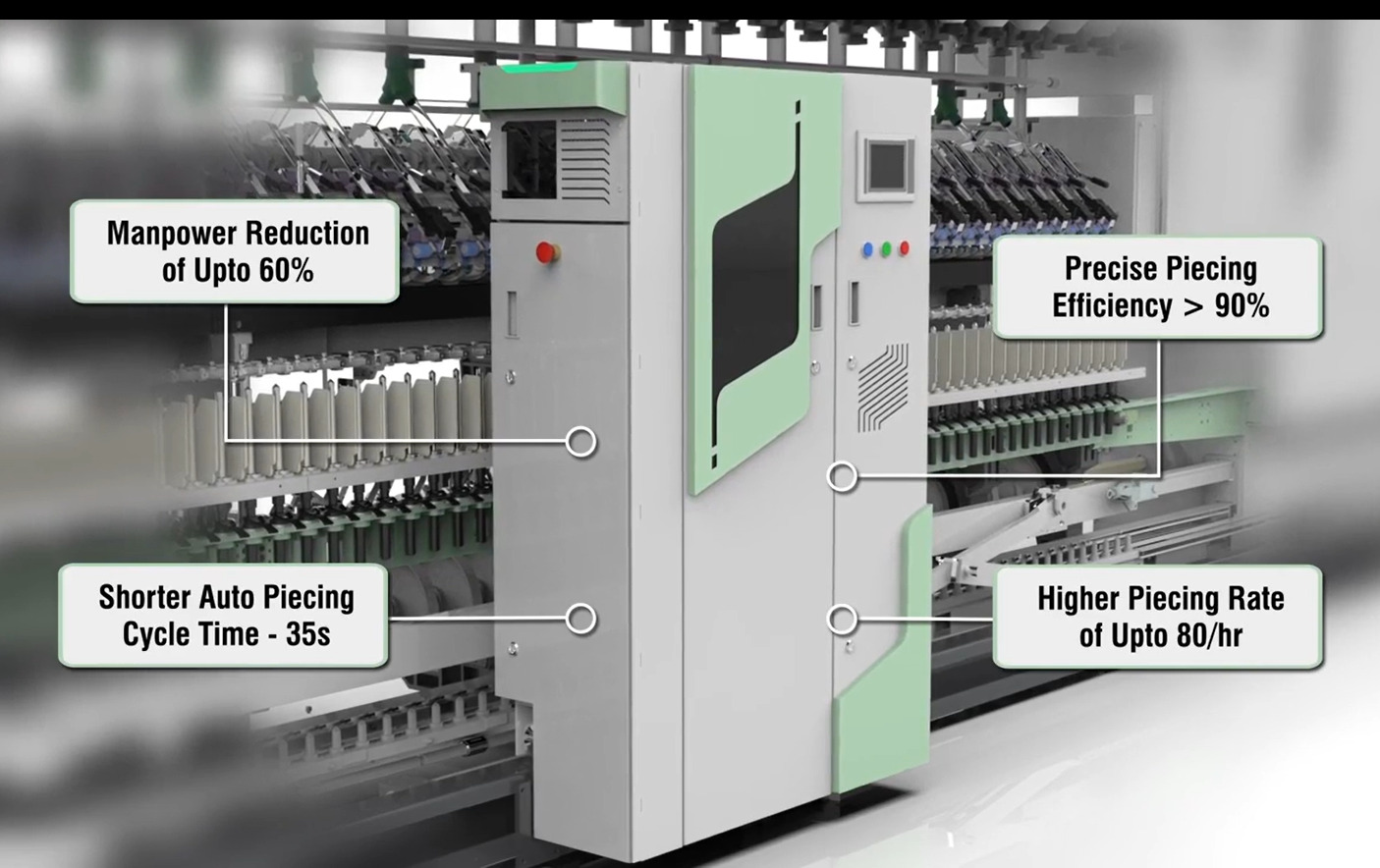

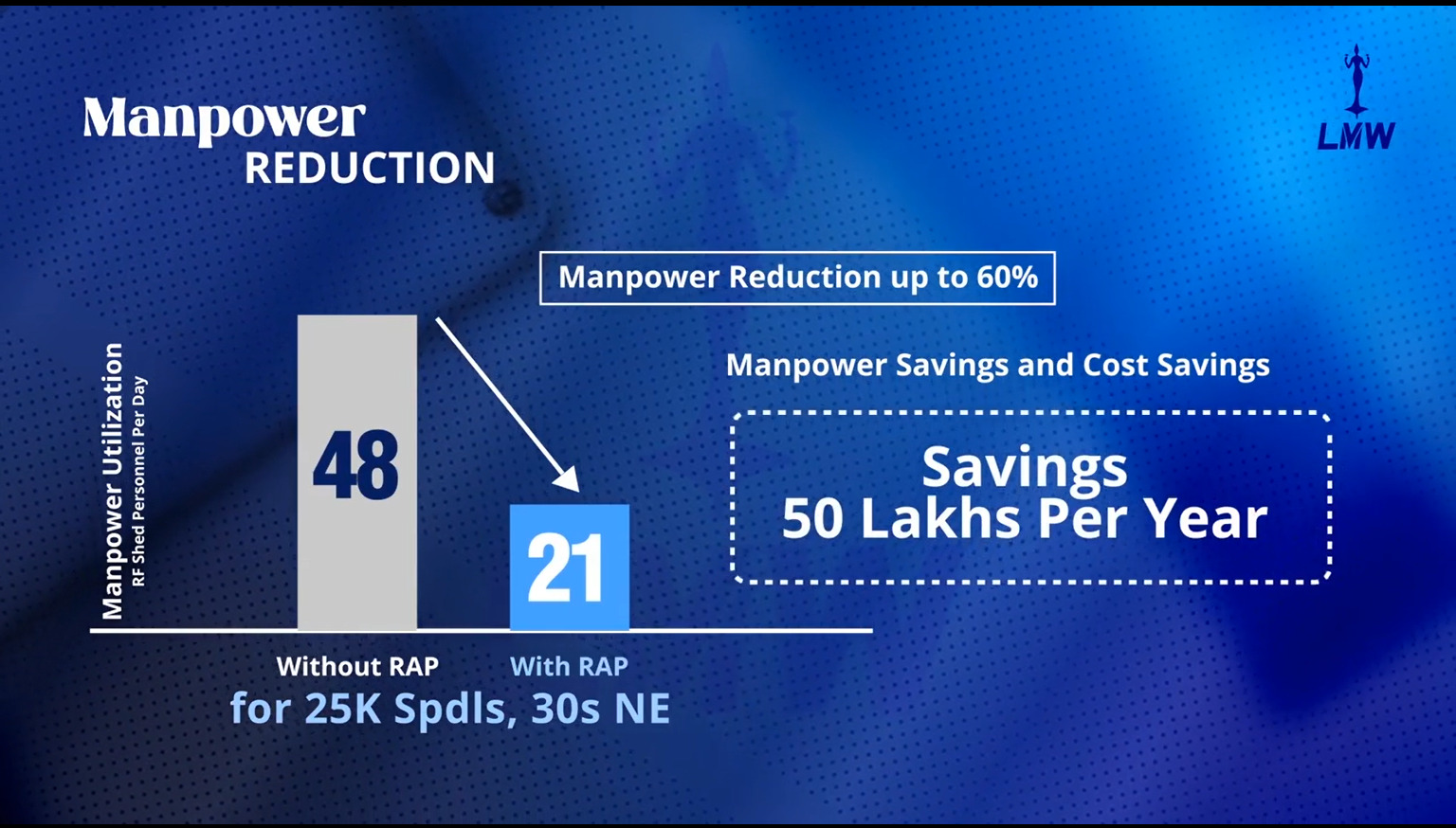

LMW Textile Machinery Division has introduced the Ring Frame Auto Piecer (RAP), a groundbreaking fully automated yarn piecing system designed for Ring spinning machines. This innovative technology significantly improves efficiency and quality in the spinning industry by automating the piecing process traditionally performed by skilled labor.

Advanced Automation with RAP

The RAP system receives real-time information on yarn breaks through the Yarn Breakage Sensor (YBS). Upon detection, RAP swiftly travels to the specific spindle and automatically pieces the yarn, mimicking the precision and technique of a human operator. This automation addresses the critical issue of skilled manpower shortage in the spinning industry, particularly in Ring spinning. By reducing dependency on skilled labor, RAP not only streamlines operations but also minimizes the need for extensive training, ensuring end mending is executed promptly to prevent production losses.

Efficiency and Productivity

RAP's advanced technology ensures immediate attention to yarn breakage with a remarkably short auto piecing cycle time of approximately 35 seconds. Operating consistently 24/7 throughout the year, RAP guarantees higher productivity, enhancing overall operational efficiency in spinning mills.

Quality Assurance

One of the standout features of RAP is its ability to maintain precise quality in yarn production. By ensuring a consistent piecing length in mended yarn and eliminating potential contamination from manual handling, RAP significantly enhances the quality of the finished product. The automated process ensures uniformity and superior quality, meeting the stringent standards of the textile industry.

Versatility and Compatibility

The Ring Frame Auto Piecer (RAP) is designed with versatility in mind, making it suitable for both Normal Ring Spinning and Compact Spinning technologies. This flexibility ensures that spinning mills can seamlessly integrate RAP into their existing operations, regardless of the spinning technology they employ.

Strategic Impact

With the introduction of RAP, LMW Textile Machinery Division reaffirms its commitment to innovation and excellence in the textile machinery sector. The automation of the yarn piecing process addresses critical industry challenges, paving the way for enhanced productivity, quality, and operational efficiency.