CIRCULAR PRODUCTION GLOBAL

By IFAB MEDIA - NEWS BUREAU - June 14, 2023 | 209 3 minutes read

In a groundbreaking partnership, Diesel, the Italian denim brand part of the OTB Group, and UNIDO (United Nations Industrial Development Organization) teamed up to create a closed-loop recycling system for fabric scraps. Their pilot project focused on capturing the value of pre-consumer textile waste and converting it into regenerated cotton fibers, which are reintroduced into the spinning and weaving process for denim fabrics.

The Italian denim brand Diesel, part of the OTB Group, has partnered with the United Nations Industrial Development Organization (UNIDO) on a pilot project to create a closed-loop recycling system for fabric scraps. The goal is to achieve circular production economies in the southern Mediterranean region. Their latest project focuses on working closely with local stakeholders along the denim supply chain in Tunisia to showcase the infrastructure and processes required for the collection, sorting, and closed-loop recycling of pre-consumer textile waste.

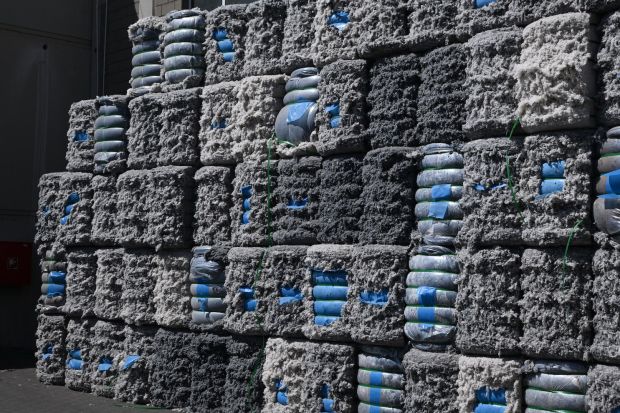

Denim scraps: Photo by UNIDO

Denim scraps: Photo by UNIDO

Diesel is about to launch 28,000 pairs of jeans made using at least 20% of recycled fibers derived from cutting waste from Diesel's Tunisian supply chain. UNIDO and Diesel have focused on creating an ecosystem of local businesses in Tunisia to valorize pre-consumer textile waste, and they've started with the separation of cutting waste at garment factories. These remains are then converted into regenerated cotton fibers using a mechanical recycling process, and reintroduced into the spinning and weaving process for denim fabrics.

"This initiative supports Diesel For Responsible Living's long-term sustainability strategy, and is helping us ensure that we meet our goals in supporting more responsible consumption and more circular production patterns, in line with Sustainable Development Goal number 12 state the United Nations 2030 Agenda," said Andrea Rosso, Sustainability Ambassador, Diesel.

According to a recent study commissioned by UNIDO, the Tunisian textile industry produces about 31,000 tons of textile waste per year, 55% of which is classified as scrap. Recycling fibers such as these could significantly reduce the industry's environmental impact by saving water, reducing carbon emissions and minimizing the release of hazardous chemicals into the environment.

Diesel and UNIDO's pilot project is part of the Switch Med Program, an initiative launched in 2013 by the European Union to accelerate the transition to sustainable consumption and production patterns in the southern Mediterranean region. The project demonstrates that capturing the value of waste within the local supply chain in Tunisia is not only technically feasible but also economically and environmentally more attractive and beneficial than transporting waste to other regions for recycling or discarding it altogether.